Papa Terra Field CP retrofit – Brava Energia & Imenco Corrosion Technology

Brava’s statement:

‘Imenco delivered their retrofit Piranha® Anode Clamp solution to us, and they helped us install it on our Papa Terra field in Q2 2025. We are very satisfied with the quality of both aspects delivered’, says Rafael Terzi and Priscilla Borges, Brava Energia Subsea Engineers.

Challenge:

At the Papa Terra Field offshore Brazil, Brava Energia identified critical cathodic protection (CP) deficiencies during routine subsea inspections. Measurements revealed that Xmas trees, RxF connectors, and choke valves had fallen below protective CP levels due to depleted anodes, exposing this critical production equipment to corrosion in the field’s challenging deepwater environment.

Solution:

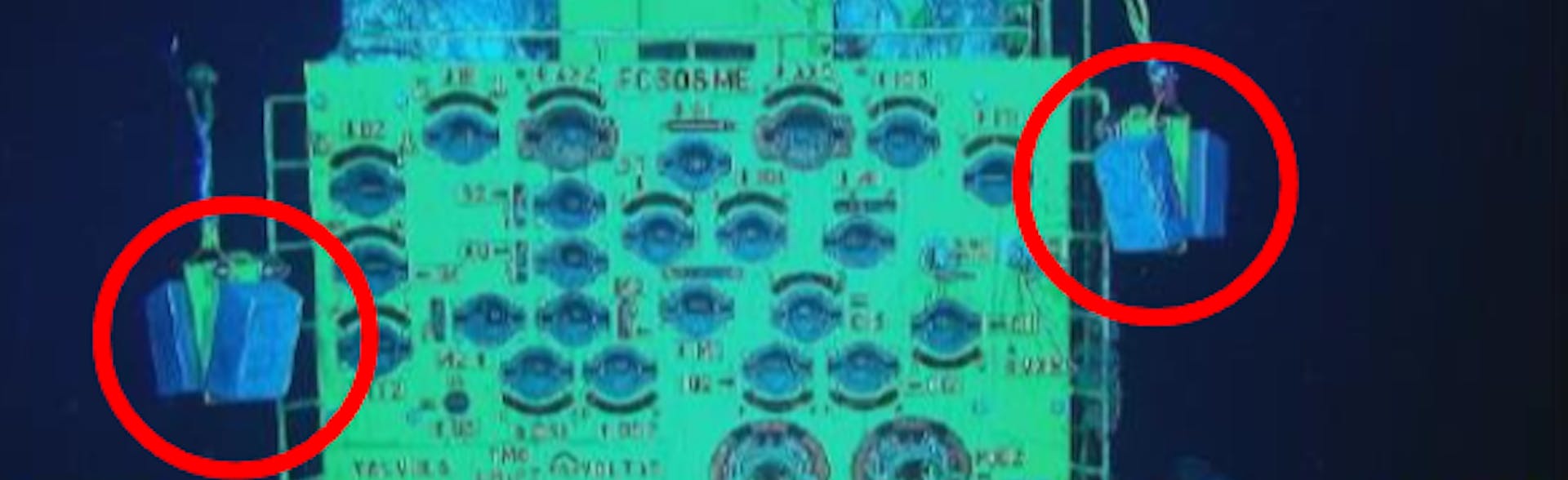

Imenco Corrosion Technology engineered a customized retrofit solution featuring:

- Piranha® Clamp System: Specially designed brackets with integrated anodes for secure attachment to complex subsea geometries

- ROV-optimized Design: Pre-assembled units enabled installation without production interruption

- Field-Adaptable Components: Multiple jaw sizes with onboard technical support ensured fast installation and optimal use of vessel time

- Precision Engineering: Anodes sized to deliver 10 years of full protection

·

Benefits:

- Environmental impact: By extending the life of the assets, therefore reducing future intervention with our Piranha® Clamp System significantly cuts down on the CO2 emissions associated with manufacturing and transporting new equipment. This contributes to a substantial decrease in the environmental footprint of offshore operations.

- Fast Operations: Rapid installation with ROV, excellent electrical conductivity, very strong mechanical grip.

·

Result:

The team successfully:

- Completed all retrofits within the planned operational window

- Restored optimal CP levels across all protected components

- Established reliable 10-year corrosion protection for critical equipment

Key Success Factors:

1. Collaborative Execution

- Seamless coordination between Brava Energia’s operations team, ROV crew, and Imenco’s Technical/Commercial team.

- Real-time problem solving by onsite technical specialist

Photo 1: Imenco technician conducting precision testing and calibration of Imenco Clamp Installation Tool (ICIT) to ensure correct installation torque would be applied.

Photo 2: ICIT interface

2. Technical Superiority

- Piranha® clamps’ 10-ton axial load capacity ensured secure mounting in strong currents

- Modular design accommodated all component variations without modification

- Extensive track record with more than 4000 clamps installed worldwide